|

Introduction

An automatic Backwash strainer is a device installed in a pipeline to remove

dirt and other unwanted debris from fluids. Straining is accomplished by

directing the fluid through sized openings in wedge Grooved type, perforated

or mesh straining elements.

Automatic Backwash strainers have integral backwash systems designed to

isolate and clean a small portion of the element while the remaining area

continues to strain normally.

During operation, fluid flow through the strainer is continuous. A small

portion of the fluid being strained is used to carry the concentrated debris

through the backwash system away from the strainer.

Automatic Backwash strainers are installed where continuous removal of

debris from the process fluid is required and where fluid flow cannot be

interrupted for cleaning the straining element.

These automatic Backwash strainers are used where manual cleaning

is not convenient or practicable for reasons such as the need for

frequent cleaning, possibility of strainer not being cleaned when

required due to remote location, variable loading rate, etc.

Trapped debris is retained inside straining element, cavities resulting

high-pressure drop in the system, these accumulated solids are then

back-washed through the backwash system.

Automatic Backwash strainers are rated to withstand the pressures of

the piping system design.

Automatic Backwash Strainers are used to protect equipment such as

valves, pumps, motors, heat exchangers or spray nozzles, as well as in

feed water and process water applications or virtually any similar

application.

How to Operate

When necessary to shut down the system, put strainers on Back-Wash

operation only for 5 minutes to clean the straining elements close the

inlets and outlets valves; open the drain valves fully and then switch

on the strainers cover the chamber drain valve should also be fully

opened. Do not allow the straining elements to dry up.

All internal parts of automatic Backwash strainer are made of

stainless steel SS-304.

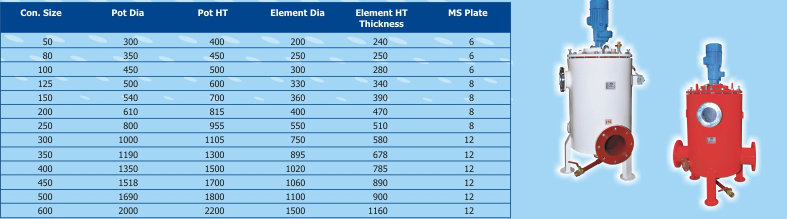

Construction

Body is fabricated out of M.S plate IS 2026. Thickness of sheet &

sizes are be as per table below, chamfered pipe with flanges are

provided at inlet / outlet connections of the Automatic Back Wash

strainer.

The Automatic Back Wash strainer body has two separate chambers

properly sealed to avoid mixing of filtered and unfiltered water.

A powerful magnet is provided in the body to arrest MS particles.

Filter Element

A) Outer Filter is made out of Stainless Steel wire mesh Gr. SS-304

having 100 mesh with wedge Grooved type to have more surface area

for better cleaning & shall be removed after flushing the system and

before commissioning.

B) Inner Filter is made out of 01 mm thick non-magnetic stainless steel

having 03 mm perforation (40 mesh) Gr. SS-304 properly reinforced to

avoid Damage of the element.

Enginnering for Excellence

Emerald had this in mind when designing Automatic Back-Wash Strainer

Series EAR-112. The priority: to make quality and economy inherent in the

above series.

This design has been made to meet the requirements of our valued clients.

Quality

Emerald Automatic Back-Wash filter has been manufactured with quality in

mind. This design will provide trouble-free services to customers. This design

is adopted by so many American and European countries.

|