|

Specification

Emerald provides a range of electric heater batteries and controllers to suit most

air conditioning and ventilation applications.

Sheathed elements provide a clean and safe method of air heating.

These heaters are intended for use in applications where the air leaving

temperature is below 40°C (70% RH db).

The heaters are available in 3 model types:

|

|

|

Circular Duct Heaters

Comprise of a circular duct section manufactured from 0.9 mm or 1.2 mm

galvanized sheet steel

Suitable for ISO standard spiral ducting from 100 mm to 500 mm diameter.

Factory-fitted galvanized sheet terminal box.

Element banks are sized to give a range of steps and phases.

The heater can be connected to the ducting system using flat clamps.

|

|

|

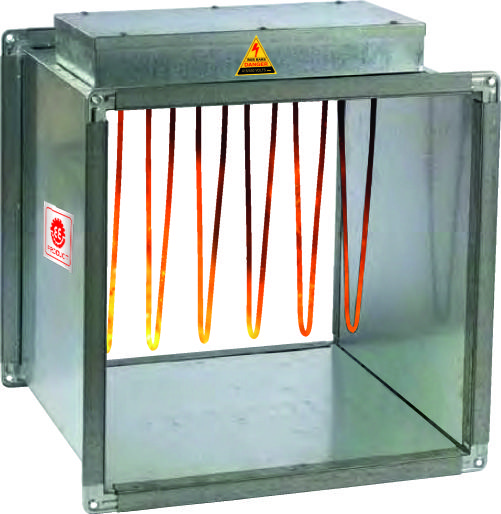

Square & Rectangular Duct Heaters

Manufactured from 0.9 mm or 1.2 mm galvanized sheet steel.

Fitted with 25 mm Ductmate flanges

If width or height < 600 mm: Total perimeter = 1800 mm.

If > 600 mm: Ductmate flanges = 35 mm, perimeter = 1800 mm.

Factory-fitted terminal box and element bank sized to suit duct size and

heating load.

Element box with complete terminal bank is removable for easy

inspection/service without dismantling the duct work.

|

|

|

Elements

Elements are constructed from Nichrome 5 spiral resistance wire surrounded by magnesium oxide power and sheathed in stainless steel, Copper pipe duly chrome plated evenly spread over the open area of the duct and secured into the terminal box. The elements are either linked with a copper bushbar or fitted with a terminal as required to achieve step and phase control requirements.

Heaters are designed to have a black heat surface temperature of 4000c at an air velocity of 2.5m/s

|

|

Panel

Fabricated out of 16G CRC Sheet, duly powder-coated, with the following

controls.

Panel is attached with the heater battery & internally wired with the heater.

Front Panel Controllers.

1. Fan on/off heater rocker switch.

2.

Power on indication.

3.

Heater on indication.

4.

Manual/auto reset indication.

5.

Fan run indication.

6.

Fan failure indication

7.

Door inter lock system

7.

Voltmeter.

Connections

1.

Electric heater battery.

2.

Supply fan.

3.

Temperature sensor via duct or room thermostat.

4.

Airflow switch(normally open)

5.

High temperature cut-out (an integral part of a heater battery)

5.

BMS – on demand.

High Temperature

A high-temperature cut-out is provided:

To protect the system and element bank.

It activates in cases of design temperature excess.

Wired in series to ensure heater shuts down until the fault is rectified.

Manual Reset

This is manually reset once the fault has been corrected.

Auto Reset

Automatically resets once temperature drops to the preset level.

Essential: Ensure fan airflow is maintained; otherwise overheating may occur

Recommended for standard electric heaters.

Auto or manual cut-out can be selected based on design standards.

IMPORTANT

A run on timer must be incorporated into the control system to allow the fan to

run on after the heater has been switched off to dissipate any residual heat.

|

Heater Selection

Calculate heater duty

Output=air volume x constant x temperature rise

Kw=m3/ s x 1.25 x ^t0c

Order Details

When ordering please state the following information

1.

Type of heater- Circular, Duct Mounted, or Stab-in

2.

Air Volume(m3/s)

3.

KW Loading

4.

Electrical Supply (220 to 240)V 1Ph or (380 to 415)V 3Ph

5.

Number of Steps

6.

Duct Size-Width x Height or Diameter(mm)

7.

Vertical Airflow if Required

8.

Any Special Requirements

Care must be taken when positioning the heater to prevent any damage or

overheating of any other equipment in the system.

IMPORTANT

It is the responsibility of the final installation or commissioning person on

site to ensure that all safety control interlocks function correctly and to shut

down systems or part systems as designed to do so, within several seconds of

activation.

|

|

TECHNICAL DATA

Maximum Leaving Air Temperature 400C

Maximum Element Temperature

4000C

Maximum Air Velocity

6m/s

Voltage

(220 to 240)V 1Ph or (380 to 415)V 3Ph

Three Phase Connection

Star connection 3 wire for step control or 4 wires for

thyristor control

Electrical Testing

Flash Tested at 1750 volts for 2 seconds.

Insulation Test

1 Meg Ohm Minimum

Manual

1. Always fit an isolator for

maintenance of the heater.

2. It is important that all

electrical connections are properly made. Elements are tested prior to dispatch

and are within a tolerance of +-71/2 W. If the elements are found to be faulty they can be easily removed and replace. Elements

stored in dap conditions may need drying to attain correct insulation readings.

3. Supply to heater should be

1ph or 3Pgh with Separate neutrals-Refer to nameplate.

4. Cables should be silicone

rubber, Fiberglass or similar high temperature insulated type and be installed.

5. The heater is fitted with a

high temperature cutout which has NC(normally closed) terminals. This must be

connected in series with the main contractor coil circuit, to isolate the heater

in the event of over-temperature(i.e. airflow failure).

6. Ensure sufficient earth connection

to terminal provided.

|